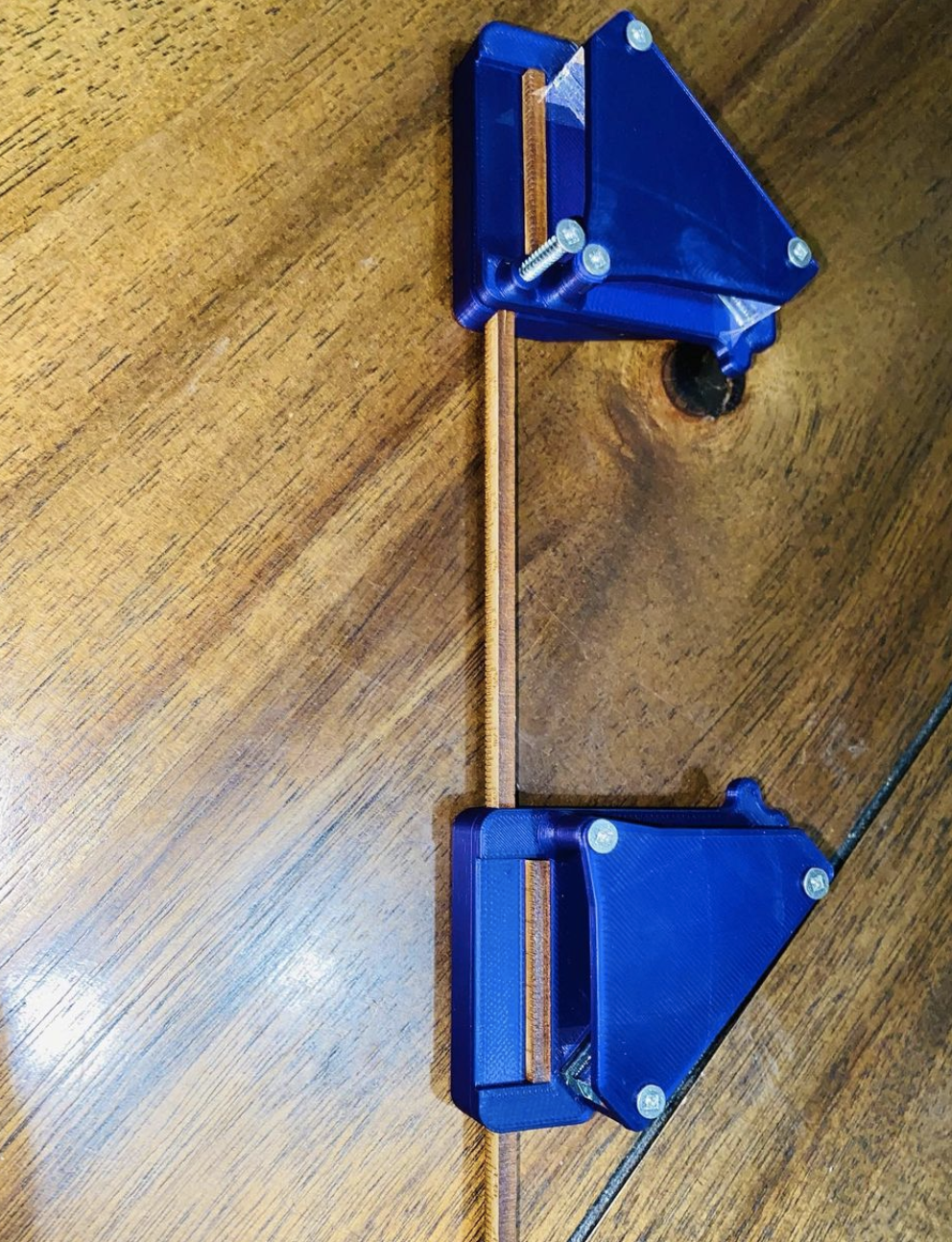

3D-printed Hertel Exophthalmometer

Designed by M. Shayyan Wasim, Mason Kraushar, Dr. Michael Mak, Dr. Michael Kryshtalskyj, and Dr. David Plemel

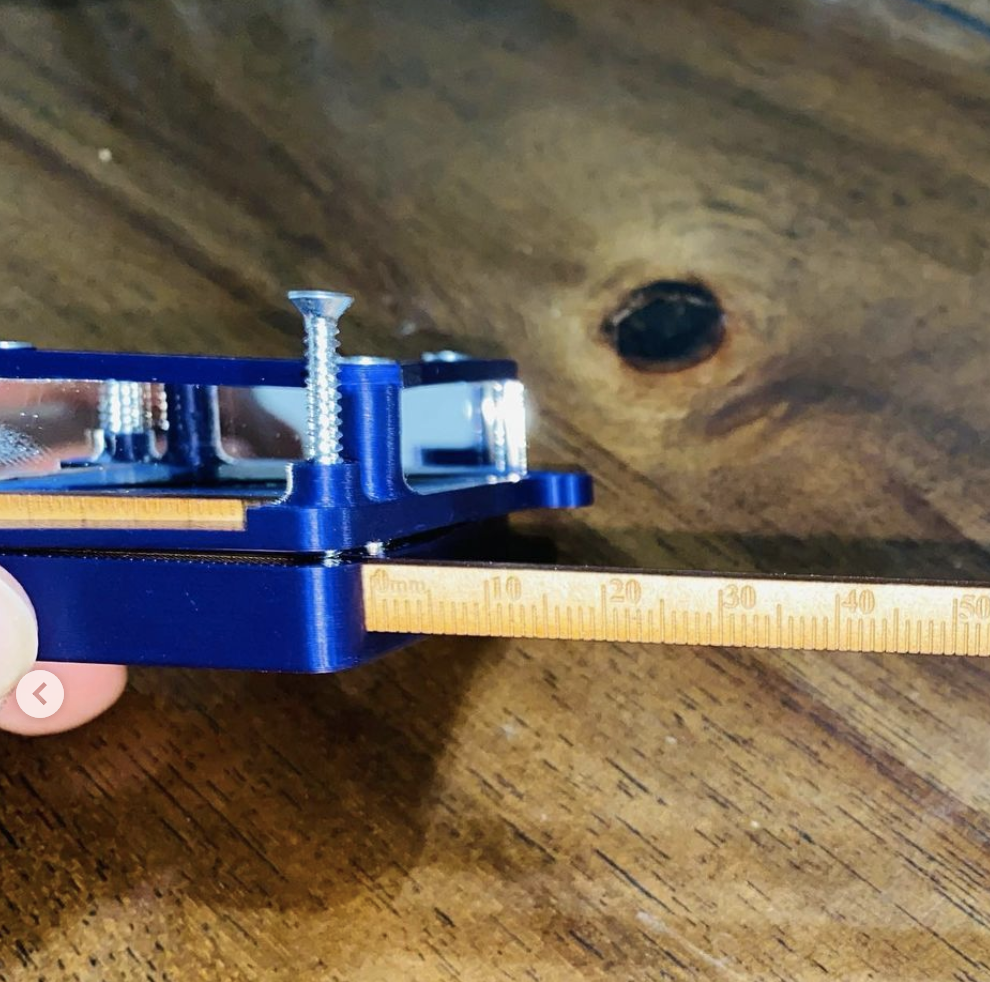

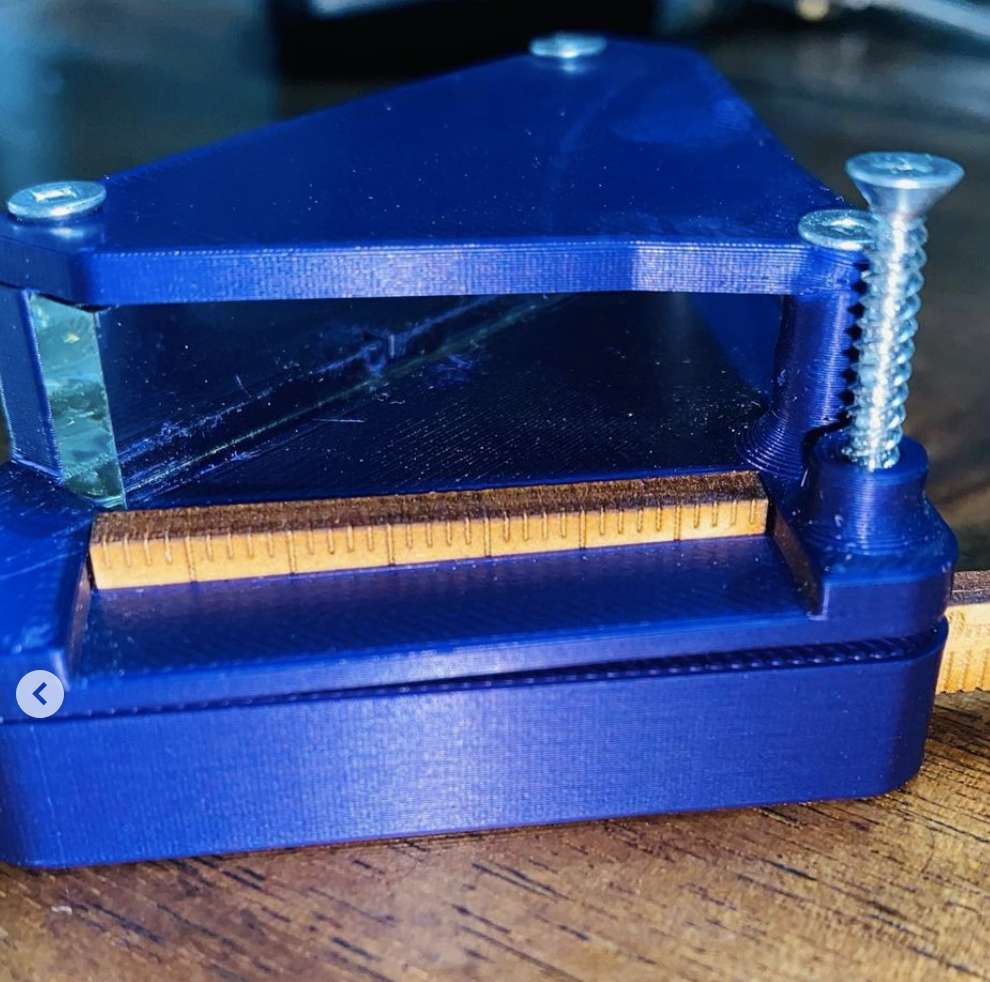

Our 3D printed Hertel had to meet two main requirements; firstly, it had to be constructed with a durable but affordable material, that was safe to sanitize. Secondly, it needed to be accurate in the axial positions of the eye when compared to commercial exophthalmometers. To accomplish these goals, we utilized 3D printing and commonly available materials, such as MDF and mirrors. This model was drafted on Solidworks (Dassault Systems, France). Using polylactic acid filament (Prusa Research, Czech Republic) on the Prusa MKS3+ printer (Prusa Research, Czech Republic), where we printed the bases of our Hertel. Afterwards, we engraved medium density fibreboard (Moulure Alexandria Moulding, USA) and cut two small mirrors from a sheet of mirror (Taiwan Mirror Glass Enterprise Co., Taiwan), using superglue (Gorilla Glue Inc., USA) and screws (H. Paulin and Co., Canada) to connect the pieces.